技術的更迭替換,未來對于各項零部件、中端組件的需求一定是要求更精密、更精良的。我國要實現“先進制造”轉型,意味著產品要求更高品質、生產更高效,還要降低企業的成本,提高企業的效益。方方面面,都離不開自動化的升級

With the replacement of technology,the future demand for various parts and mid-end components will definitely require more sophisticated and sophisticated.Our country's"advanced manufacturing"transformation means that products require higher quality and more efficient production,and it must also reduce enterprise costs and improve enterprise efficiency.All aspects are inseparable from automated upgrades

3C行業從最初的手工、半自動到機器人,再到自動化流水線設備配合機器人,最后到未來的智能工廠,是一個從自動化到信息化最后邁向智能化的發展趨勢。

3C industry from the initial manual,semi-automatic to robot,then to automatic assembly line equipment with robots,and finally to the future intelligent factory,is a development trend from automation to informatization and finally to intelligent.

目前自動化流水線設備在3C行業主要應用在沖壓、打磨、拋光、噴涂及測試等環節,其他環節如分揀、包裝、裝配目前自動化程度普遍較低。

At present,automatic assembly line equipment in 3C industry is mainly used in stamping,grinding,polishing,spraying and testing,and other links such as sorting,packaging,assembly are generally low degree of automation.

3C制造業產品大多生命周期比較短、工藝變化比較大,產品自動化生產技術可實現行及資金投入大,因此自動化程度較國外更低。

The life cycle of most 3C manufacturing products is relatively short and the process change is relatively large.The automation degree of 3C manufacturing industry is lower than that of foreign countries because of its short life cycle and large capital investment.

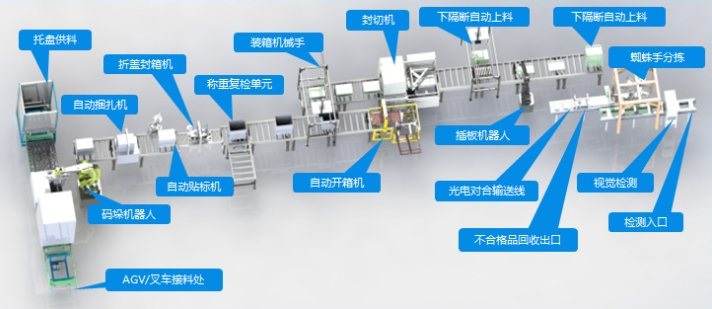

3C行業全自動裝配流水線是一款自動化裝配線智能改造設備,打造無人化車間。人工將檢測后的光電板放入對合輸送線上,對合后經機械手插入各班的固定槽內,蓋上上隔板,將整層產品放入L型封切機和熱封機機型包裝和熱封紙箱。

3C industry automatic assembly line is an automatic assembly line intelligent transformation equipment to create an unmanned workshop.Manually put the detected photoelectric board into the closed conveyor line,insert it into the fixed slot of each shift through the manipulator,cover the upper partition board,and put the whole layer of products into L-type sealing machine and heat sealing machine type packaging and heat sealing carton.

經自動開箱并輸送到產品裝箱位置進行裝箱,整個動作由坐標機械手完成。

After automatic unpacking and transportation to the product packing position,the whole action is completed by the coordinate manipulator.

裝箱后,經過稱重裝置稱重檢測,不合格經過剔除輸送回收處理,合格品經過封口、貼標和碼垛。

After packing,after weighing and testing by weighing device,unqualified products are removed,transported and recycled,and qualified products are sealed,labeled and palletized.

碼垛托盤放入碼垛上料口,開啟自動運行系統自動碼垛。

The pallets are put into the palletizing feeding port,and the automatic operation system is started for automatic palletizing.

整個過程只需要幾名工人備料和運料即可,整個過程全自動高效運行。

The whole process only needs a few workers to prepare and transport materials,and the whole process is fully automatic and efficient.

3C行業自動化流水線設備的生產工藝流程:

The production process of 3C industry automatic assembly line equipment is as follows:

1、外觀視覺監測

Visual appearance monitoring

2、蜘蛛手分揀

Spider hand sorting

3、隔板上料

Partition loading

4、產品對合并輸送

Combined transportation of products

5、下隔斷上料

Lower partition feeding

6、多關節機械手插板

Insert plate of multi joint manipulator

7、上隔斷上料

Upper partition feeding

8、封切機

Sealing and cutting machine

9、坐標機械手裝箱

Coordinate manipulator packing

10、自動開箱機

Automatic box opener

11、稱重復檢

Weighing recheck

12、拆蓋封箱機

Cover removing and sealing machine

13、自動貼標

Automatic labeling

14、自動捆扎

Automatic strapping

15、多關節機械手碼垛

Multi joint manipulator palletizing

16、托盤供料

Pallet feeding

自動化流水線設備在3C行業的應用,核心技術在于制造和裝配,3C產業的工業機器人可以有力的降低人力成本、提高工作效率、并降低成本。

The application of automatic assembly line equipment in 3C industry,the core technology is manufacturing and assembly.The industrial robot of 3C industry can effectively reduce human cost,improve work efficiency and reduce cost.

不管是時代的發展,還是市場的飽和度,國內3C制造業自動化率還有很大的提升空間。未來新的星迅,或將在這里出現!

Regardless of the development of the times or the saturation of the market,there is still much room for improvement in the automation rate of the domestic 3C manufacturing industry.The new singsun in the future may appear here!

《免責聲明:本站部分內容來源互聯網,旨在分享,如有關于作品內容、版權或其它問題請及時聯系!》